To keep a roof structurally healthy, you need to do more than just fix visible damage. You also need to know how weight, materials, and hidden stress affect each other over time. In Madison, AL, where seasonal weather shifts can challenge even the best-built structures, professional roofers focus on safe layering and weight control to extend the lifespan of each roof system. Precision, not speed, defines how a roof repair company maintains long-term balance between structure and performance.

How Multiple Roof Layers Influence Structural Weight Distribution

Each added roof layer changes how the weight spreads across rafters and decking. A single layer of shingles might seem light, but when combined with underlayment, flashing, and additional coatings, the load multiplies. Over time, this can cause deflection or sagging if the framing was never designed to bear the added mass. For roof repair near me searches in Madison, professionals carefully calculate total system weight before layering to avoid hidden overloading risks.

What surprises many property owners is that older roofs often conceal multiple generations of material beneath the surface. Layering saves money in the short term, but also changes the weight restrictions of the structure over time. The more layers there are, the more stress there is on trusses, fasteners, and joints. This makes what seems like a quick fix a structural problem.

Evaluation of Decking Strength Before New Material Installation

Before installing a new surface, contractors evaluate the integrity of the roof decking. This wood or composite layer forms the base for shingles or membranes, and its strength directly affects how much weight the structure can support. Madison roof repair specialists measure moisture content, nail retention, and flex resistance to determine whether the decking needs reinforcement or replacement.

This inspection process also reveals subtle issues such as rot or delamination, which can spread beneath visible layers. A full evaluation makes sure that the new materials stick together well and that the load stays steady once installation starts. It’s one of the most important steps before any roof replacement or restoration.

Removal Protocols for Aged Roofing to Prevent Excessive Layering

Layer buildup often starts from a desire to save time. Instead of removing old shingles, contractors may install new material over existing layers. However, professionals trained in roof repair understand this practice creates uneven surfaces and added weight that can accelerate deterioration. Safe removal is key to preserving long-term structural integrity. Removal involves a controlled process to strip each layer without damaging the decking below. Teams working on roofing near me projects in Madison often use pneumatic tools and waste management systems to handle debris quickly and safely. The goal is to start each new installation on a clean, level foundation that supports optimal adhesion and performance.

How Professional Inspections Detect Hidden Load-bearing Strain

Inspections go far beyond visual checks. Roof repair experts utilize specific tools like thermal imaging and moisture meters to find stress points that are concealed under the surface. These diagnostic tools reveal areas where weight has caused sagging or where trapped moisture is weakening support beams.

Detecting load-bearing strain early allows contractors to address the problem before it becomes critical. Experts can estimate where the next weak spots will be by looking at the slope uniformity and frame alignment. For property owners searching for roof repair near me in Madison, this approach minimizes risk and prevents larger structural damage from forming unseen.

Reinforcement Measures Applied to Older Roofing Frameworks

In older homes, trusses and rafters often weren’t built with modern load standards in mind. Roof repair companies in Madison apply targeted reinforcement techniques to keep these structures compliant and secure. Reinforcements may include adding sister beams, metal brackets, or new sheathing layers to strengthen existing framing.

Such reinforcement distributes the roof’s weight more evenly, preventing localized stress that leads to cracks or deflection. The method used depends on how old the roof is, how steep it is, and how it was built. Done properly, it extends service life without requiring a full roof replacement.

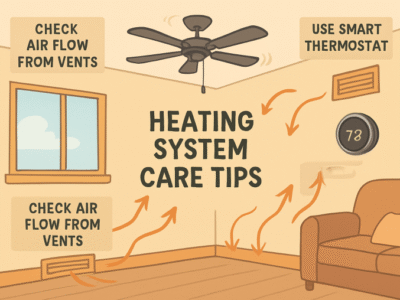

Balancing Insulation Layers Without Compromising Ventilation Flow

Thermal efficiency is important, but you need to find a balance between insulation and ventilation. If you put vapor barriers in the wrong place or too much insulation, they might retain moisture, which alters the pressure and weight inside the attic. A good roof repair firm moves insulation around to keep the temperature stable while allowing air to flow freely.

Ventilation stops moisture from building up in Madison’s humid climate, which can degrade decking and corrode fasteners. To keep both comfort and structure safe, roof repair experts typically add ridge vents or soffit apertures to balance heat and moisture. It’s a technical but important part of the roofing equation.

Why Improper Layering Leads to Premature Roof System Failure

Too many layers accelerate wear from the inside out. Too much weight compresses the underlayment and weakens the points where materials stick together, which can cause cracks and leaks. Once one layer fails, the entire system’s durability is compromised.

The lifespan of the roof also drops significantly under unbalanced loads. Tiles or shingles may slip, flashing may fall free, and water may get in. Proper removal and relayering ensure that new materials function as designed, preserving both appearance and structural safety.

Techniques Contractors Use to Maintain Safe Load Thresholds

Experienced roofers in Madison use a combination of measurement, testing, and weight distribution planning to stay within safe load thresholds. They calculate pounds per square foot and adjust installation patterns to prevent weak spots. Modern software helps determine whether additional layers can safely be added or if removal is mandatory.

These contractors also verify that each supporting component, from decking nails to truss joints, meets safety codes for the expected load. Through precise load mapping and cautious installation, professional teams protect buildings from future sagging or failure.

Comments